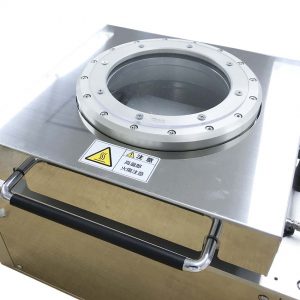

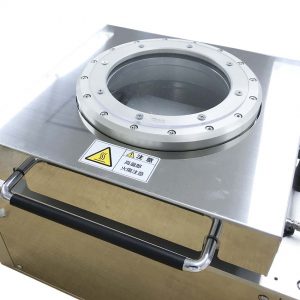

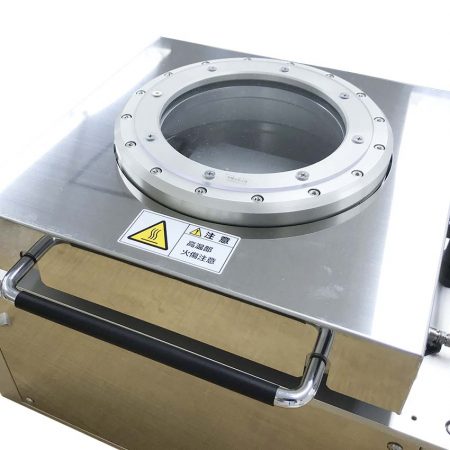

High vacuum heating and drying furnace Chamber PH226, max. temperature 400°C

Main applications

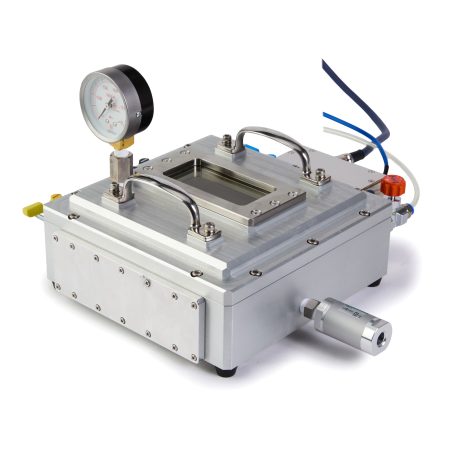

HIGH VACUUM HEATING PROCESSES VACUUM BAKING, VACUUM DRYING FURNACE, AND VCD. THE COLOR TOUCH PANEL TEMPERATURE CONTROLLER / PCC118-HVMJ ENABLES EASY OPERATION OF THE VACUUM HEATING PROCESS.

MSA FACTORY HEATING KNOW-HOW

We combine various know-how such as heater design, thermal insulation, and thermal radiation. The software is also highly functional.

Simple main unit + abundant options for a variety of applications

With a simple main unit and controller, high-temperature and vacuum processes can be built for as low as 4 million yen. A wide variety of options and customization options allow you to build a model that is best suited for your company.

Option list is here PH224_225_OP1 *Please contact us for other options.

PH225 catalog is here PH225 catalog (English version PH225_EN)

high efficiency

Uniform heating is possible due to hot plate heating. Workpiece processing time is also short, and we invite you to compare the time with conventional processes.

Long-time heating/ultra-high temperature vacuum heating

Supports heating processes exceeding 1 hour and ultra-high temperatures (400°C). For extended workpiece handling, water-cooling function (optional), chiller and circulating cooling water are required separately.

safety

The controller is equipped with safety functions that include an over-temperature monitoring function, an emergency stop function, a leakage current detection function, and a load disconnection function.